I’ve been spending some time lately going through some old pictures and thinking about the enormity of the task of taking these photos and scanning them into my computer to preserve them. Not that I think 20 years from now we’ll be using compact discs or flash drives to store photos, but who knows.

The coolest and most technically intricate generators in the MUSE fleet were the generators driven by gas turbine engines. We had two very different models; a 750 KW generator set driven a Solar Gas Turbine engine, and this one, a 2000 KW generator driven by an Allison Gas Turbine engine. The engine in this generator set, a model we called the 501KB, was also used in turboprop aircraft such as the C-130 cargo plane (in which it had the model designation T-56). For our use, instead of driving the propeller, the front shaft went through a reduction gear-box and then spun a generator. It was a complex unit, using a small 150 hp gas turbine as the starting motor for the larger engine. These were built by Morrison – Knudson in

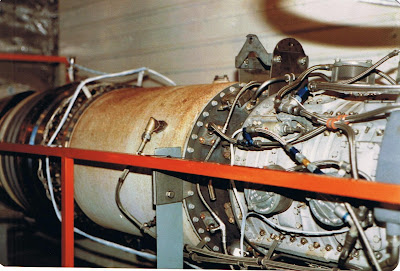

The coolest and most technically intricate generators in the MUSE fleet were the generators driven by gas turbine engines. We had two very different models; a 750 KW generator set driven a Solar Gas Turbine engine, and this one, a 2000 KW generator driven by an Allison Gas Turbine engine. The engine in this generator set, a model we called the 501KB, was also used in turboprop aircraft such as the C-130 cargo plane (in which it had the model designation T-56). For our use, instead of driving the propeller, the front shaft went through a reduction gear-box and then spun a generator. It was a complex unit, using a small 150 hp gas turbine as the starting motor for the larger engine. These were built by Morrison – Knudson in  Here is one of the three control panels for the generator. The generator included a fire suppression system. These generators were not what you would call fuel efficient, using 250 gallons of jet or diesel fuel per hour at full load. But that wasn’t the point – they were the most power-dense generator we had: 2,000 KW of power in a highway legal trailer. It could get almost anywhere very quickly.

Here is one of the three control panels for the generator. The generator included a fire suppression system. These generators were not what you would call fuel efficient, using 250 gallons of jet or diesel fuel per hour at full load. But that wasn’t the point – they were the most power-dense generator we had: 2,000 KW of power in a highway legal trailer. It could get almost anywhere very quickly. Here is a shot of the engine. The starting system included a complicated sequence to avoid ‘compressor stall’, which can result in melted turbine blades, which is, ummm, not good.

Here is a shot of the engine. The starting system included a complicated sequence to avoid ‘compressor stall’, which can result in melted turbine blades, which is, ummm, not good.

Here is a picture of me and Barney Baker taken at

One of my favorite deployments during my MUSE years was the trip to

What is a ‘shock test’? It’s when you take a new class of ship, bring it a few miles off shore, and then detonate explosives underwater that are progressively larger and closer to see how the ship reacts. It’s a sort of stress test for ships. What made this test unique was that it was the first shock test performed on a nuclear powered surface vessel. We were there (don’t laugh) in case the reactor scrammed, and the emergency generators failed also. We were supposed to come alongside, run and connect cables into the ships electrical system, and provide power for the reactor emergency core cooling system (ECCS) and other critical systems. We practiced the drill a few times before the actual tests. It also meant that we had to be very nearby during the test, once we were closer than the ship to the explosives. Which meant all of our ‘stuff’ had to stay together too. Which it didn’t. Which is another story.

Well, we’re getting long here, so let’s call this generators part one. More next time.